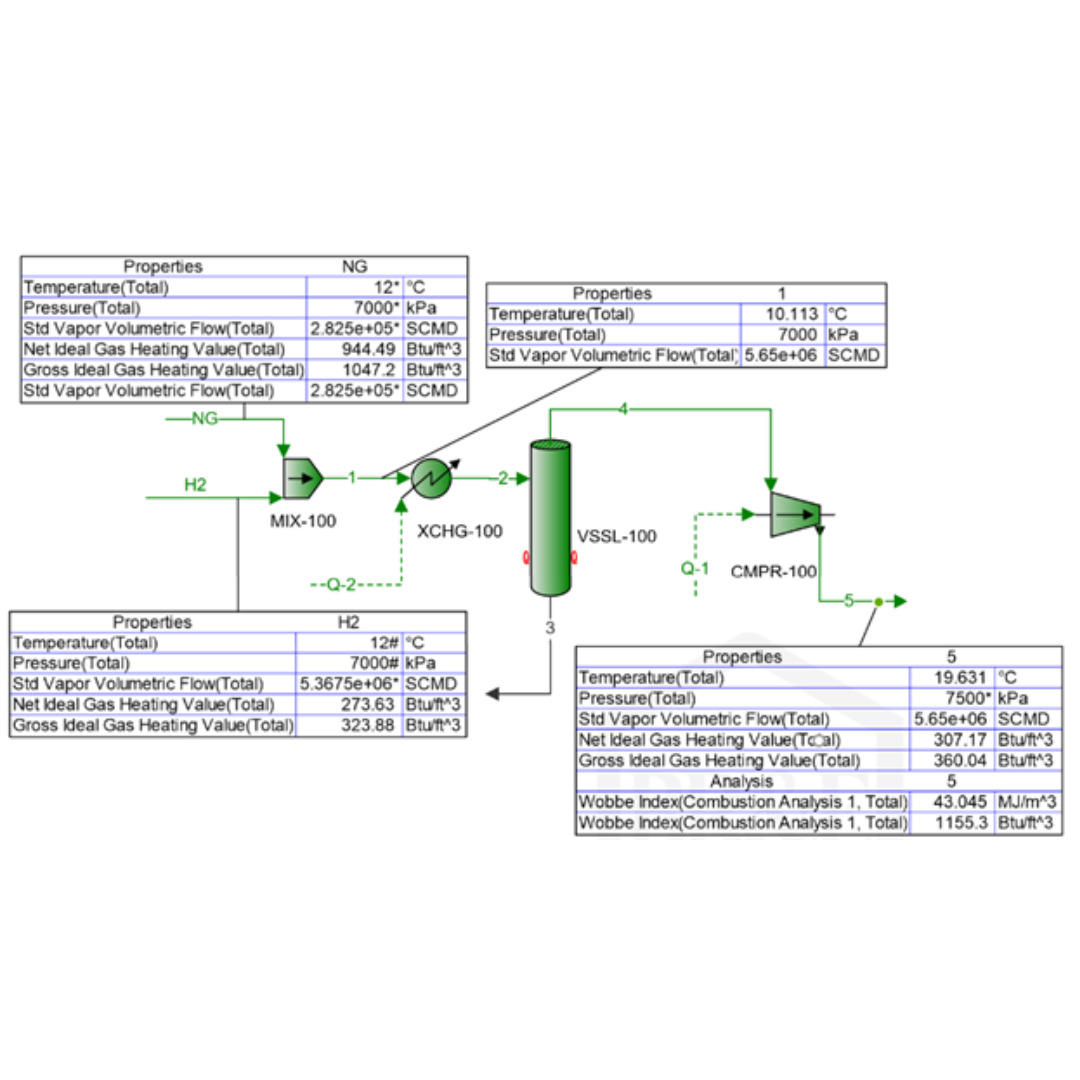

This article describes simple equations to approximate changes to the properties of crude oil with changing temperature. Changes in crude oil density and specific heat, or heat capacity, can be estimated from graphs and/or more elaborate computer simulation. The latter generally requires access to a process simulator and characterization data for the crude oil. A suitable, tuned computer model is likely the most accurate method of estimating the fluid properties, but is not always available. Direct laboratory measurement is also possible if facilities and oil samples are available and a high degree of accuracy is required. [Keep reading]