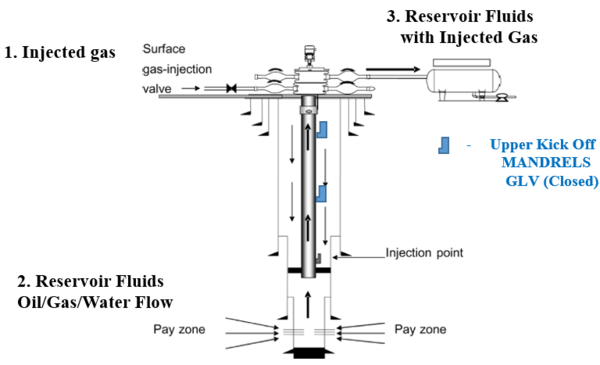

In this Part 1 presentation of the initial Gas – Lift series, and effort has been made to provide for initial orientation regarding the important Gas – Lift history, initial background, initial production efforts, Gas – Lift components, and design criteria. Oil and Gas production has been an integral part of the World’s energy based economy for over 160 years. Improvements in new GLV designs were implemented after the 1940’s. In all GL applications, however, the pressure and volume of the injection gas was difficult to control due to the limited numerical models available to predict the Valves’ “CHOKE PERFORMANCE”. Injection Gas is injected down the tubing casing annulus through a series of “kick – off” (well flow initiation) Mandrels containing the applicable GLV, or the standing GLV at the bottom of the tubing string. The Mandrel is a single section of the production tubing string that allows insertion of the selected GLV. The solution Gas Oil Ratio, Rs, (GOR related in SCF/STB) is the gas that the reservoir oil has in solution in an oil reservoir at a specific pressure and temperature. This gas is liberated as the formation fluid is transported to the surface. The amount of flowing free gas will depend on the oil rate. The Oil Formation Volume Factor, Bo (Bbl/STB), also plays an important role in the solution gas being liberated by flowing pressures and temperatures. [Keep reading]