Onshore Gas Gathering Systems – Concept Selection, Basic Design & Operation (Part 1)

Onshore Gas Gathering Systems – Concept Selection, Basic Design & Operation

By: Mark Bothamley

(Part 1)

Conventional vs Unconventional Gas Field Development

Shale gas is typically considered an “unconventional” resource, along with tight gas and coalbed methane. Of these three, coalbed methane (CBM) has several characteristics that make it quite different than shale gas and tight gas, including: shallow depth, low pressure and temperature, and the need for a significant early life “de-watering” stage. As a result, CBM developments have some considerably different aspects to them and will not be discussed further in this article.

There are a number of characteristics that differentiate Conventional and Unconventional gas field developments. A summary of these characteristics is presented in Table 1.

Table 1 Conventional and unconventional field characteristics

Associated and Non-Associated Gas

While the discussion in this article is focused on gas field development (non-associated gas), oil operations must also collect and transport solution gas (associated gas) to a gas plant for processing. Many of the issues discussed here will be relevant to these systems as well.

Conventional Gas Fields

The defining characteristic of “conventional” gas fields is higher reservoir permeability, which in turn results in the following features:

1. Relatively high flowrates.

2. Relatively low decline rates.

3. High flowing tubing pressures in the early years.

4. Large well spacing.

5. Mostly vertical wells and single-well surface sites.

By and large, the geology of conventional reservoirs also tends to make them smaller in areal extent than shale/tight gas reservoirs. Most conventional reservoirs have an areal extent of less than a few hundred square miles while shale gas plays can cover tens of thousands of square miles.

These characteristics have a significant impact on surface facilities design and operation, including the gas gathering system (GGS).

Unconventional Gas Fields

Perhaps not surprisingly, the main characteristic of unconventional gas fields is very low reservoir permeability. In order to achieve economic gas flowrates and recoverable reserves, these reservoirs typically require massive fracture stimulation treatments and, for the shales at least, long horizontal wellbore sections, in order to vastly increase access to formation surface flow area to offset the very low native permeability of the rock. The following features are typical of shale/tight sand developments:

1. Small bottomhole well spacing.

2. Pad drilled wells.

3. Relatively high initial production rates.

4. Rapid production decline.

5. Fairly early onset of well liquid loading problems due to lower production rates after the first few years, which usually requires i) some form of artificial lift and/or ii) significantly reduced back pressure to allow the wells to keep flowing.

An additional characteristic of many shale/tight sand reservoirs is their generally large areal extent. When combined with often fragmented acreage ownership, surface facilities design and operation can become complicated.

Certainly, it is generally true that many, if not most, of the conventional onshore gas fields around the world have been discovered and mostly developed, ie. the majority of the “easy” gas reserves have already been exploited. In the future, new field developments will mainly be focused on unconventional gas resources.

Well Site/Pad Facilities

The well site/pad facilities and gas gathering system are interconnected and generally not independent. Selection and design decisions in one area effect the other. While sometimes complicated, ideally these two pieces should be considered as an interactive and integrated system. Unfortunately, this often doesn’t happen, for various reasons to be discussed.

Facilities Ownership

A factor that often affects surface facilities design and operation in certain areas, especially many unconventional gas developments, is the change in ownership at the edge of the pad, ie. between the wells and pad facilities owned and operated by the production company, and the gas gathering system (including compression and gas plant(s)) typically owned by a midstream gas gathering/processing company. This ownership “discontinuity” at the pad edge can often lead to inefficiencies and a non-optimal system overall. The gathering system entry pressure is typically the key variable.

In some parts of the world, the same company drills, produces and operates the wells, and also designs, builds and operates the gas gathering system and gas plant. In many ways, this allows for – at least in theory – a more optimally integrated overall operation. This “integrated” system ownership, ie. upstream + midstream, is less common now than in the past, as many of the large energy companies have sold their midstream assets to dedicated midstream companies.

Interacting Components

For both conventional and unconventional gas field developments, there are several interconnected - but interacting - pieces involved:

1. the reservoir.

2. the wells.

3. the wellsite/pad facilities.

4. the gas gathering system.

5. the gas plant.

In addition to the interactions between these pieces at any particular point in time, there is also a longer-term effect associated with reservoir pressure decline and a corresponding decline in well flowrates. For some gas fields, composition will also change over time, eg. leaning out of the gas due to retrograde condensation of heavier ends in the reservoir, increased formation water production, etc.

It is often difficult to evaluate these components in isolation of each other. It is the integrated aspect of GGS design and operation, and in particular, the subsurface-surface integration considerations – that has historically made this a complex area. The relatively sharp demarcation of knowledge that occurs – more or less – at the wellhead, between subsurface and surface technical people does not help matters. Integrated Asset Models (IAMs) have proven to be quite useful for modeling gathering system design and operation – including the subsurface-surface interaction aspects – especially over time. They take some effort and a multi-disciplinary approach is needed. The difference in ownership between the wells/pad facilities and the GGS/gas plants has in some cases limited the ability of IAMs to achieve their potential.

Main Surface Facilities Issues

From the surface facilities point of view, the following – in no particular order – are the key areas to be considered:

1. Avoidance of hydrates.

2. Sweet vs sour (H2S) gas.

3. Liquids handling and disposition, including multiphase flow problems (hydrocarbon liquids and water).

4. Corrosion/materials selection.

5. Line sizing considerations.

6. System architecture.

7. Provisions for future drawdown of flowing/reservoir pressure to maintain deliverability and maximize reserves recovery – mainly compression.

1. Avoidance of Hydrates

In some parts of the world, hydrate formation is not a major concern. These are normally warm regions, nearer the equator. Moving farther north and south, ambient temperatures begin to drop, including shallow ground temperatures at typical pipeline burial depths. In these regions, hydrates may be a problem in the winter but not at other times of the year. Eventually, ie. > ~ 40o latitude north and south, ambient/pipeline burial temperatures are low enough to make hydrates a problem year-round. Figure 1 shows typical hydrate formation conditions as a function of gas gravity.

Figure 1 Hydrate formation conditions.

Minimum winter temperatures at typical pipeline burial depths range from ~ 35 F in northern Alberta to ~ 55 F in the southern United States. From Figure 1, for a typical 0.65 SG gas, a flowing temperature of 35 F corresponds to a hydrate pressure of ~ 135 psig, while a temperature of 55 F corresponds to a hydrate pressure of ~ 535 psig. In many parts of the world, sales gas transmission pipelines operate at a nominal pressure of 1,000 psig. Depending on the type of gas plant used for processing, plant inlet pressures (excluding inlet compression) often range from 1,050 – 1,400 psig, with the highest end of this range being typical for a Joule-Thomson (JT) type of plant. While there are certainly a reasonable number of JT plants in operation world-wide, they are much less common than refrigeration and turbo-expander plants, resulting in a typical operating pressure range of 1,100 – 1,300 psig for most high-pressure gas gathering systems (a strong case can be made that both JT and refrigeration plants would benefit from low-temperature separator operating pressures in the 500-600 psig range which would help plant operation and reduce back-pressures on the upstream wells/GGS. The drawback is, that to do this would normally involve the installation of sales gas compression initially, with the associated high cost). These pressures are well into hydrate formation territory for typical buried pipeline flowing gas temperatures.

A potentially feasible hydrate prevention strategy might be to design and operate the gathering system at pressures below the hydrate forming pressure at the minimum expected flowing temperature. This would definitely be an option for shallow, low pressure gas fields but would not normally be desirable for higher pressure developments for a few reasons:

1. To achieve the necessary low pressures would require the early installation of compression which incurs a large upfront cost.

2. The wells may need to be choked to control flowrates which would negate any potential deliverability benefits associated with lower GGS back-pressure.

3. Low pressure operation in early field life when gas flows are typically largest will require larger pipe diameters due to the low gas density, though higher line pressure drops may be tolerable in early well life. This again, incurs a large upfront cost.

Many conventional gas reservoirs are relatively deep, eg. > 7,000 feet, and therefore at fairly high pressures, at least initially, eg. 3000+ psig. Gas wells producing from these reservoirs will generally have the capability of flowing at reasonable rates and high tubing pressures for a number of years. The wells will often be choked for flowrate control, at least in their early life. Over time, reservoir pressure will decline due to depletion, flowrates will fall, chokes will be opened, and eventually the wells will have difficulty flowing against high gathering system backpressures. At this time, it is typically necessary to either 1) drill more wells, and/or 2) install compression to reduce backpressure on the wells in order to maintain deliverability and also to maximize gas reserves recovery which is inversely proportional to reservoir abandonment pressure for “volumetric” reservoirs. While drilling more wells to maintain field deliverability may be feasible during the early years, the addition of compression will normally be required eventually.

Certainly as reservoir pressures decline over time, and compression is added, a point may be reached when the operating pressure drops below the hydrate formation pressure at the minimum prevailing GGS temperature condition. Depending on the system design, it may be possible to discontinue hydrate prevention measures in order to save operating costs and salvage equipment. This will normally mean changing from a dry to a wet system, and the implications of this would have to be considered.

Assuming the GGS will initially operate at high line pressures, the following options are available for hydrate prevention:

i. Remove the water by dehydrating the gas.

ii. Keep the gas/wellstream above the hydrate formation temperature at the prevailing pressure.

iii. Utilize a chemical to inhibit hydrate formation. There are pro’s and con’s to each of these options, and all three are used.

Remove the water, ie. dehydrate the gas.

The water content of saturated typical natural gas stream is shown in Figure 2 The water removal requirements for field dehydration applications are not necessarily the same as “sales gas” specifications but are typically similar, with the main requirement being to prevent condensation of free water out of the gas during transportation. Values of 3-7 lb/MMSCF are typical, dependent mainly on minimum ambient/flowing temperatures.

Figure 2 Water content chart for 0.65-0.75 SG sweet natural gas.

|

|

There are two dehydration methods that are normally considered:

1. Glycol (normally triethylene glycol) dehydration (probably 90+% of field gas dehydration applications).

2. Mole sieve dehydration.

A 3’rd potential gas dehydration option is calcium chloride (CaCl2), but this is typically more of a niche application – low gas flowrates, low-moderate gas temperatures – and will not be considered further in this article.

Gas dehydration also has significant benefits with respect to GGS corrosion control and materials selection.

The required dried gas outlet spec will typically be dictated by the dewpoint corresponding to the minimum flowing gas temperature (winter) in the gathering system at the worst case (highest) operating pressure condition likely to be experienced. In general, the minimum flowing temperature is mainly a function of geographical location (latitude), and to a lesser extent, burial depth of the line.

Glycol dehydration

Glycol dehydration is by far the most commonly used field gas dehydration method. For a conventional gas field development with large well spacing, eg. 640 acres, and vertically drilled wells, the glycol dehy would typically be located on the wellsite, ie. each well would have its own glycol dehy. In the author’s experience, wellsite glycol dehydration is less common now than it once was, probably because there aren’t many onshore conventional gas fields being discovered and developed anymore. In many cases, glycol dehydration has been displaced by methanol injection, which will be discussed later in this article.

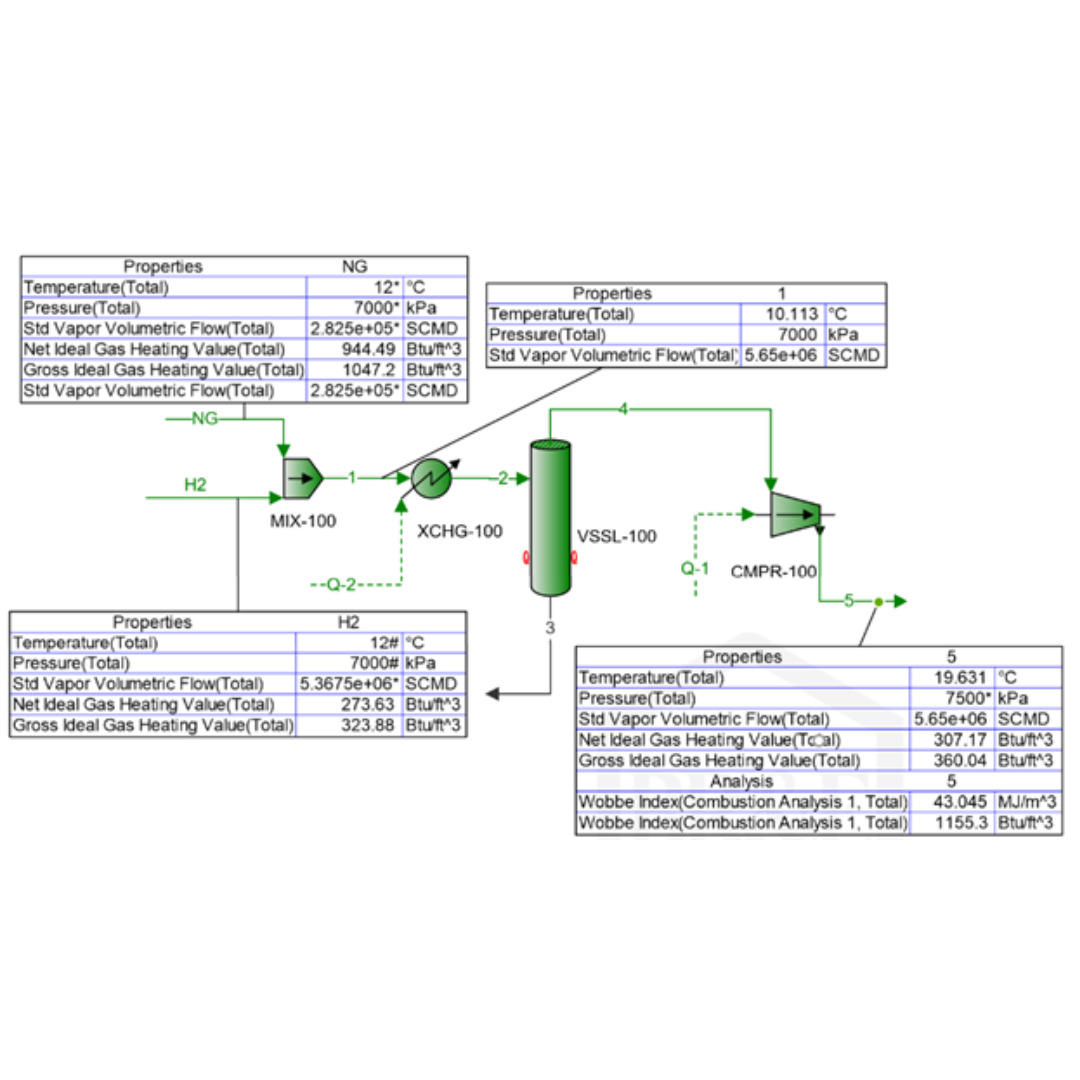

Normally, a 3-phase vertical separator with metering of all three phases is installed upstream of the dehy, or can be incorporated into the bottom of the glycol contactor vessel as an “integral” separator. Any free water is dumped to an onsite storage tank and trucked out periodically. Condensate is typically – though not always – recombined with the dried gas and multi-phased to the gas plant. Normally, the condensate/free water separation is good enough – and the amount of condensate small enough – that downstream hydrate problems caused by water in the recombined condensate are not an issue. If necessary, a condensate “conditioner” - basically a liquid-liquid coalescer - is utilized if more efficient free water separation from the condensate is needed. Liquid handling is discussed further later in this article. A typical PFD of wellsite glycol dehy facilities is shown in Figure 3. 9

Figure 3 Gas well with wellsite glycol dehydrator

|

|

Conventional wells typically flow at reasonably high flowrates, eg. 5 – 50 MMSCFD, or more, and therefore flowing tubing temperatures are also usually fairly warm and can be quite hot for high rate wells. This normally will eliminate the need for a choke heater ahead of the dehy to handle the expansion temperature drop if the well is choked to control flow. Only high flowrate wells will have flowing temperatures too high for inlet into a glycol contactor, ie. > 120-130 F. In this case cooling of the wellstream ahead of the glycol unit will be required and potentially an alternative hydrate prevention strategy should be considered. Wellsite cooling of the wellstream is fairly rare, but may be required for high flow wells.

As discussed previously, compression will likely need to be installed at some point to reduce flowing tubing pressure in order to maintain deliverability, and also to allow for lower reservoir pressure and corresponding higher gas reserves recovery to be achieved. The wellsite facilities, eg. 3-phase separator and dehy unit should be designed with an allowance for future lower pressure operation in mind, eg. allowable gas velocities, higher saturated water content of the gas and potentially increased formation water volumes.

Glycol dehydration has been used to dry sour gas streams in the field, but normally these applications have been limited to less than, say, 5 % H2S. The main concerns have been corrosion and emissions from the still overhead. Of course, all high H2S wellsite facilities require adequate safety provisions, and these are typically unattended facilities. Glycol dehys have been used on much higher acid gas concentration streams, eg. acid gas reinjection schemes, but these are typically gas plant installations with supporting infrastructure, monitoring and operations personnel present.

Wellsite glycol dehydration tends to be more cost effective – compared to methanol injection – for higher flowrates. There are significant economies of scale related to the CAPEX of a glycol dehydration unit as size increases whereas methanol costs increase approximately linearly with gas flowrate.

Methanol injection provisions at the wellsite should always be provided as backup for the dehy, cold startup conditions, etc.

Solid Bed (Mole Sieve/Silica Gel) Dehydration

Many will be surprised to learn that solid bed dehydration would even be considered for a field wellsite application, and for good reason. Solid bed dehydration is more complex and expensive than glycol dehydration and its main advantage over glycol – very low dried gas water content/dewpoint – is not normally needed in gas gathering operations. In the relatively few circumstances where a wellsite mole sieve system has been used, it has been for a high H2S application, eg. typically > 20 % H2S. The main advantage of this process compared to glycol dehydration is that with high pressure regeneration, most, if not all, of the H2S emissions can be eliminated. Figure 4 shows a sour gas wellsite equipped with a solid bed dehydration system.

Figure 4 Wellsite molecular sieve dehydration unit

|

|

Union Carbide

Although these systems have occasionally been installed, they are uncommon. Most high H2S gas fields tend to use heat for hydrate prevention instead of dehydration, and this option is discussed next.