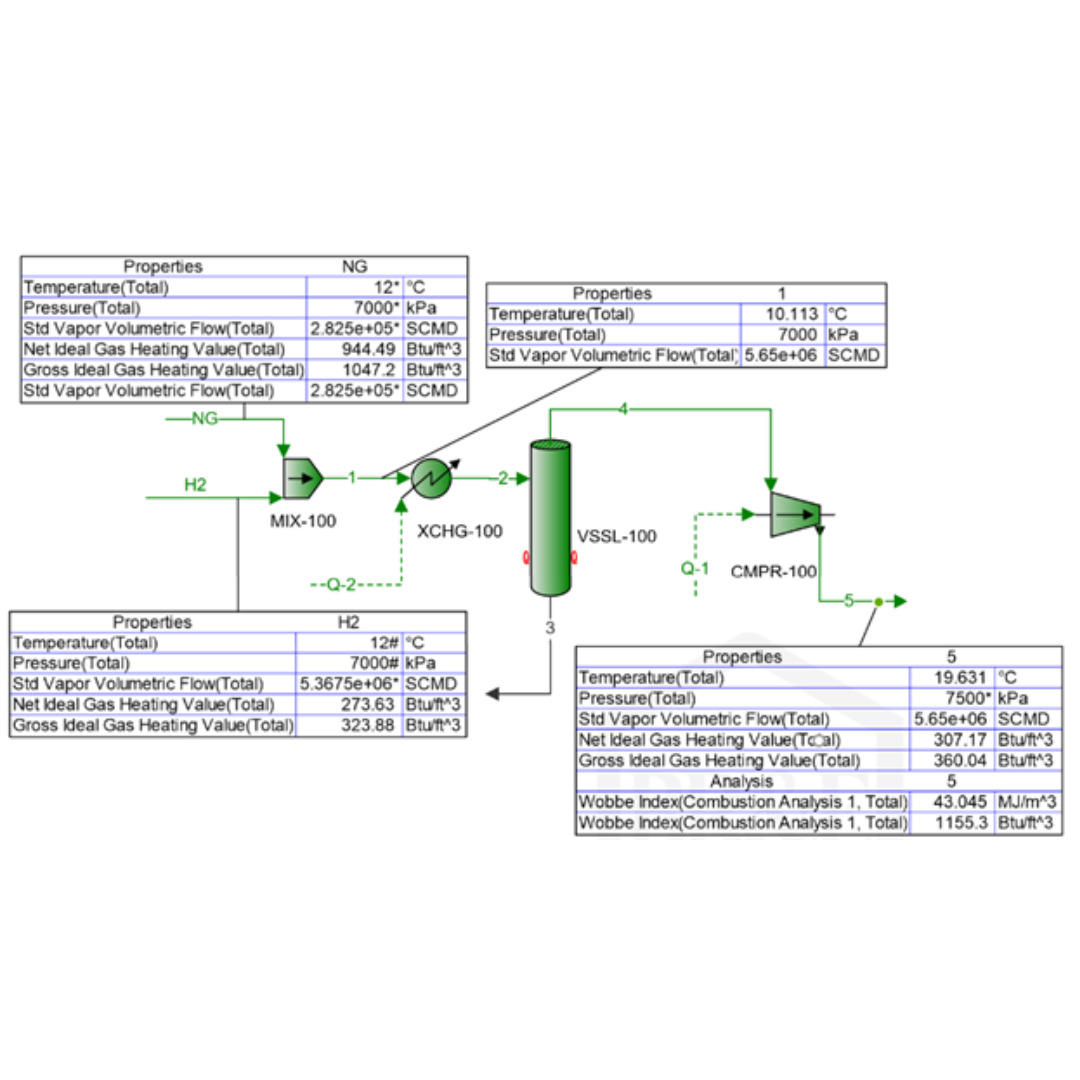

In continuation of Feb 2023 “Tips of the Month” (TOTM) and given the amount of investment and interest in hydrogen, we have decided to publish a series of TOTM to explore the opportunities, challenges, and potential solutions to hydrogen applications and uses; this is the second paper in the series. As such, we will continue this exploration with hydrogen compression and transportation by transmission pipeline systems – what are the permissible conditions and restrictions? This TOTM does not cover the pipeline materials compatibility issues, which will be a focus of another tip. In terms of the compression characteristics, what are the technical challenges for deployment? Specifically, we explore the possibility of blending a relatively pure hydrogen stream with a natural gas residue to supply 5.65x106 SCMD (standard cube meter per day) or 200 MMSCFD fuel gas to a heavy industrial unit. With the aim of achieving net zero, the objective is to maximize amount of hydrogen in the fuel gas by replacing hydrocarbons while meeting pipeline tariff and sales specifications. [Keep reading]